Powerful Power Services

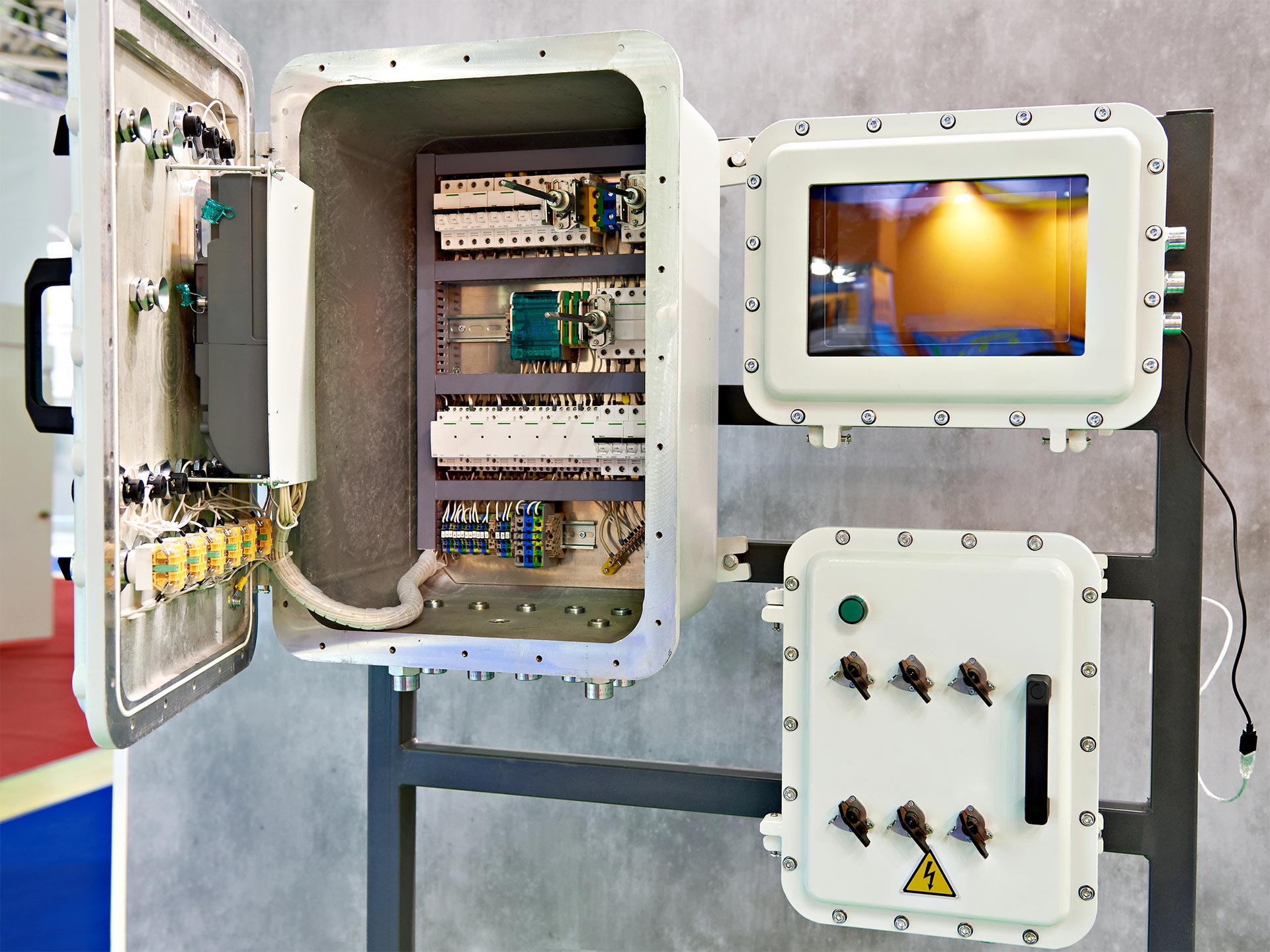

E.ILE has extensive experience and specialized staff for such projects, undertaking the study, supply and installation of electrical applications of anti-explosive type ATEX, in areas where there is a possible risk of explosion and / or fire.

Our company provides comprehensive services for Anti-Explosive type Facilities and the maintenance of their equipment, selecting the highest quality materials on the market, primarily to protect our employees, but also our materials / products and facilities, from the risk of possible explosion and / or and fire.

Most anti-explosive installation systems have four success factors, which are:

Some anti-explosive systems also have isolation systems using chemicals and mechanisms to avoid high pressure or the passage of flame through pipelines or connected pipes, leading to other areas of our facility with equipment. These isolation systems are activated within five milliseconds when detecting an explosion or fire.

Explosion detection devices operate by identifying warning signs of an explosion or fire. These devices are responsible for when the suppression system and / or the explosion isolation system should be activated. Thus, explosive detection devices play a key role in preventing or reducing explosions and fires, which can cause serious physical harm, as well as material damage to our facilities.

Explosion supression Systems are designed to detect and suppress explosions before the situation leads to irreversable damage. This system is essential to prevent and / or reduce injuries, deaths and property damage.

Explosion-proof isolation systems work to prevent a fire from escaping from the point caused by another, through the use of chemical barriers and explosion-proof isolation valves, which are critically fast to respond. These systems work perfectly in conjunction with explosive ventilation systems.

The chemical method of isolation involves the release of an agent so that the isolation of the explosion can normalize the fire, preventing it from spreading to other equipment and / or areas of our facility.

Explosion-proof ventilation systems serve and protect against high-pressure, industrial-hazardous explosions, creating an escape route for explosive gas.

Browse some of our projects:

Who are mainly concerned

Conditions for a possible explosion, as a result of various reasons, can be created in several workplaces, such as:

Such installations pose a risk of leakage of their materials, resulting in the presence of oxygen in the air, causing ignition and consequently explosion. This applies to gases, vapors, droplets and powders of various materials, which in combination with the widely used in the electricity industry, can cause sparks or the creation of hot surfaces, where when they come in contact with the above forms of various materials, in combined with oxygen, to ignite and consequently explode and / or cause a fire.

The purpose of an ATEX type of electrical installation in such facilities is to reduce the risk of explosive and / or fire conditions, within an acceptable level.